Tube Bending

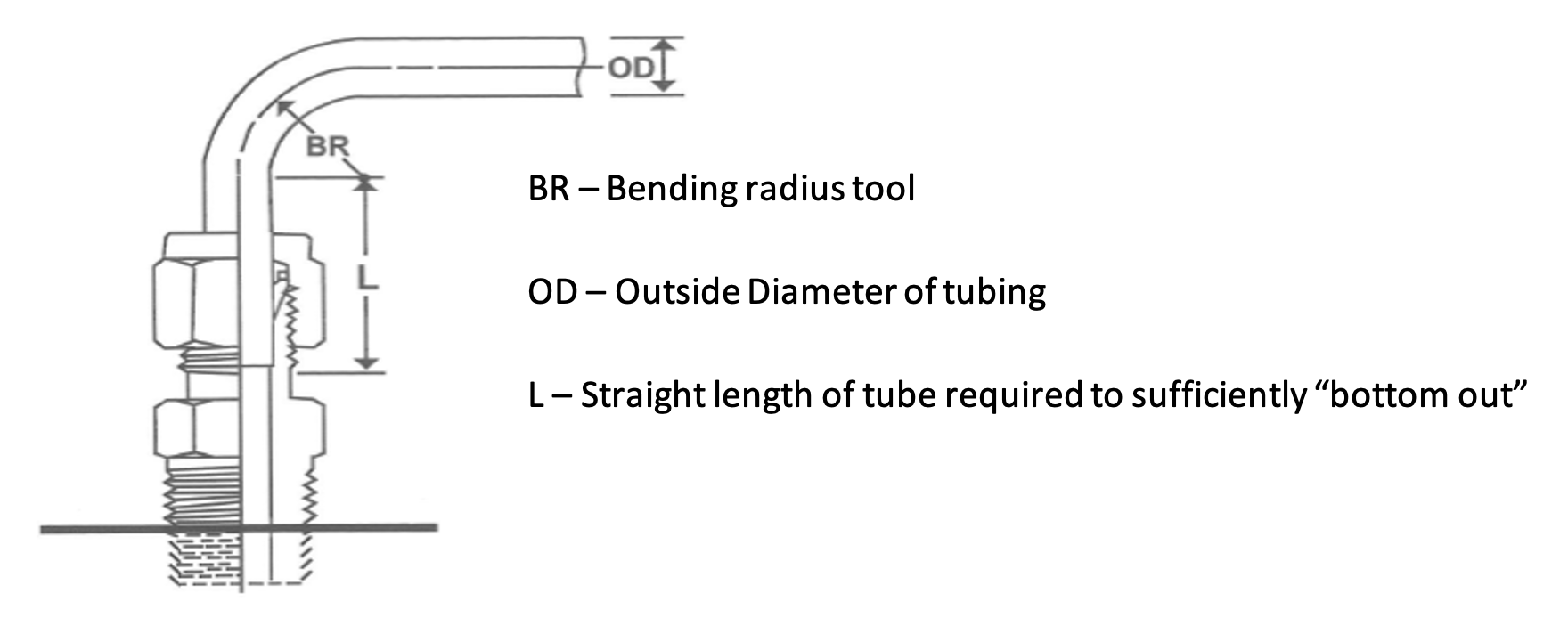

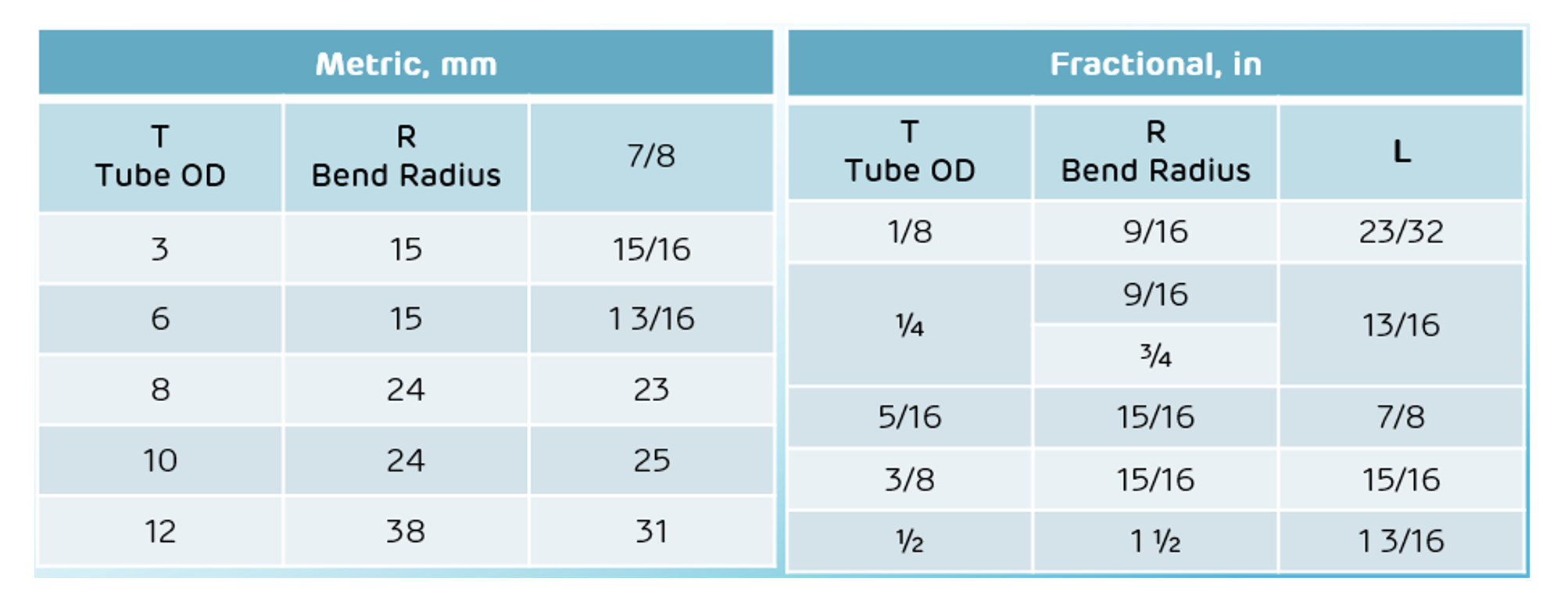

If you are installing components next to bends you must leave enough straight tubing so that the tube can sufficiently bottom out into the fitting.

- Cut the tube, this can be done with a tube cutter (with the correct blades) or a hacksaw and guide to ensure a square cut (hacksaw should have at least 32 teeth per inch, this helps avoid burns)

- Tube must be deburred correctly on both the OD and ID to get a good seal and prevent particles getting into the SBT system medium

- Clean tube and inspect - there should be no marks or damage on the surface of the tubing.